Linije za panelne limove

Lines for panel plates

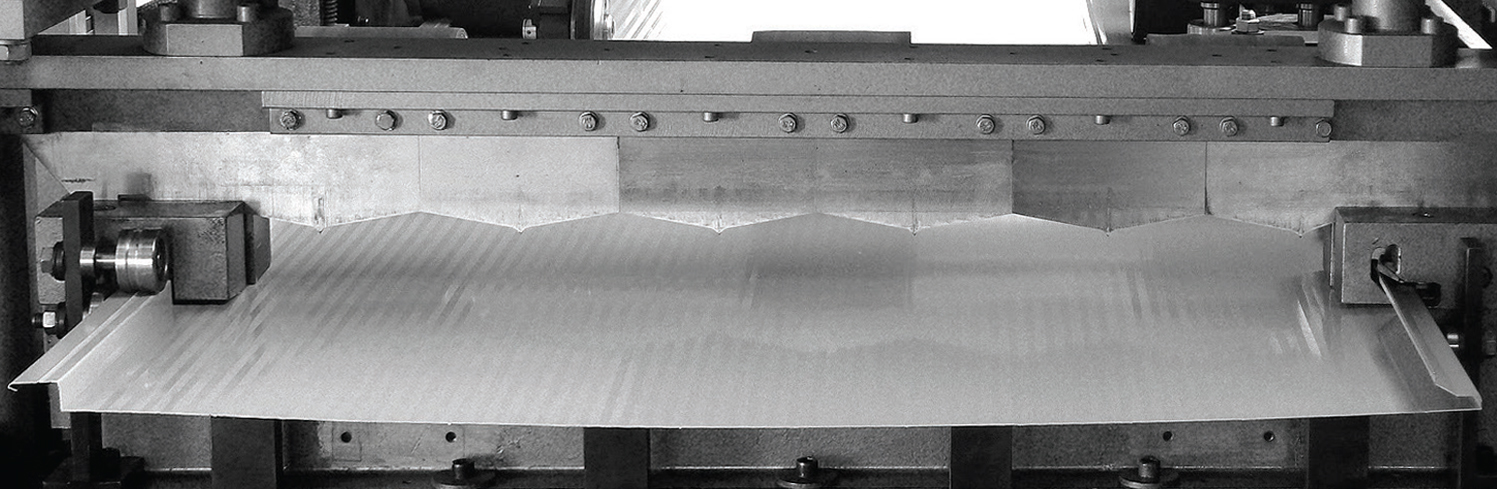

Linije za proizvodnju panelnih limova različitih oblika sa mogućnošću ugradnje u kontinualne i diskontinualne linije za proizvodnju sendvič panela.

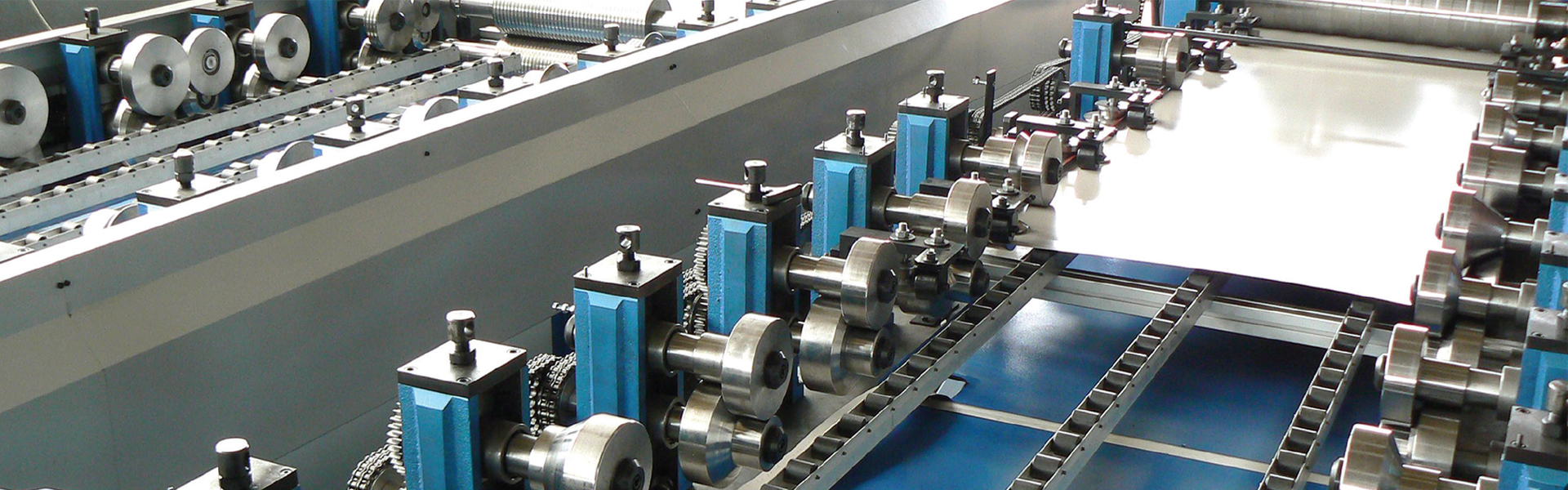

Lines for production of panel plates of various shapes with possibility of fitting in continuous and discontinuous lines for production of sandwich panels.

Metal-Produkt je renomirana kompanija koja proizvodi linije za panelne ploče sa mogućnošću ugradnje u kontinualne i diskontinualne linije za proizvodnju sendvič panela. Proizvodi Metal-Produkta su kvalitetni i efikasni, dovode do bržeg i preciznijeg procesa proizvodnje sendvič panela.Linije za proizvodnju panelnih ploča su neophodne u građevinarstvu za proizvodnju sendvič panela različitih oblika i dimenzija.

Proces proizvodnje sendvič panela počinje odmotavanjem lima.Limovi se utovaruju da bi se započeo proces proizvodnje sendvič panela. Linija Metal-Produkt sadrži mehanizam velike brzine koji nudi nizak otpor prilikom ubacivanja lista u presu.

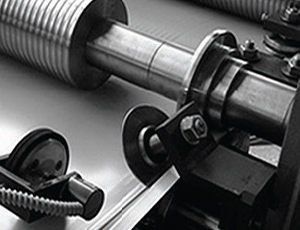

Nakon što se lim odmota, počinje proces proizvodnje. Početni korak u proizvodnji sendvič panela je spajanje slojeva u presu. Linije Metal-Produkt panela omogućavaju naprednu tehnologiju presovanja koja garantuje čvrstu i sigurnu vezu između slojeva sendvič panela.

Nakon presovanja sledi oblikovanje sendvič panela. Linije ploča Metal-Produkt imaju napredne mehanizme koji su dizajnirani da oblikuju panel u različite oblike i veličine. Ova faza u proizvodnji sendvič panela omogućava izradu panela prema zahtevima naručioca.

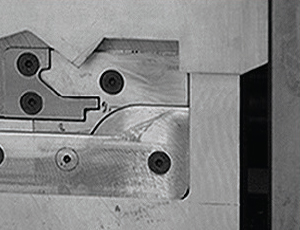

Poslednji korak u procesu proizvodnje sendvič panela je sečenje u željene dimenzije.Proizvodne linije Metal-Produkta poseduju tehnologiju sečenja visoke preciznosti koja ne troši nikakav materijal, obezbeđujući efikasnost i smanjenje troškova.Nakon izrade linija se transportuje do kupca.

Metal-Produkt linije karakterišu napredni transportni sistemi koji transportni proces čine veoma efikasnim.

Nakon transporta sledi završna faza u procesu proizvodnje – montaža panel mašine, testiranje i puštanje u proizvodnju. Metal-Produkt nudi usluge montaže, ispitivanja i puštanja u rad, što garantuje da će proizvodna linija raditi nesmetano i da će se postići visok nivo produktivnosti.

U zaključku, linije za proizvodnju panelnih ploča su neophodne u građevinskoj industriji i ključne su za proizvodnju sendvič panela različitih oblika i veličina. Metal-Produkt je kompanija koja nudi napredne linije za proizvodnju panelnih ploča koje su efikasne i precizne i garantuju brzu i kvalitetnu proizvodnju sendvič panela.

Sa proizvodnim linijama Metal-Produkt a, klijenti će dobiti mašinu koja će biti efikasna, produktivna, kvalitetna i koja će zadovoljiti sve njihove zahteve.

Metal-Produkt is a renowned company that produces lines for panel boards with the possibility of installation in continuous and discontinuous lines for the production of sandwich panels. Metal-Produkt’s products are of high quality and efficient, they lead to a faster and more accurate sandwich panel production process. Lines for the production of panel boards are necessary in the construction industry for the production of sandwich panels of various shapes and dimensions.

The sandwich panel production process begins with the unrolling of the sheet. The sheets are loaded to begin the sandwich panel production process. The Metal-Produkt line contains a high-speed mechanism that offers low resistance when feeding the sheet into the press.

After the sheet is unrolled, the production process begins. The initial step in the production of sandwich panels is to join the layers in a press. The lines of Metal-Produkt panels enable advanced pressing technology that guarantees a solid and secure connection between the sandwich panel layers.

After pressing, the molding of sandwich panels follows. Metal-Produkt’s panel lines have advanced mechanisms that are designed to shape the panel into different shapes and sizes. This stage in the production of sandwich panels enables the production of panels according to the customer’s requirements.

The last step in the sandwich panel production process is cutting into the desired dimensions. The production lines of Metal-Produkt have high-precision cutting technology that does not consume any material, ensuring efficiency and cost reduction.

Metal-Produkt lines are characterized by advanced transport systems that make the transport process very efficient.

After transportation, the final stage in the production process follows – assembly of the panel machine, testing and release into production. Metal-Produkt offers assembly, testing and commissioning services, which guarantees that the production line will run smoothly and that a high level of productivity will be achieved.

In conclusion, panel production lines are indispensable in the construction industry and are crucial for the production of sandwich panels of various shapes and sizes. Metal-Produkt is a company that offers advanced lines for the production of panel boards that are efficient and precise and guarantee fast and high-quality production of sandwich panels.

With Metal-Produkt production lines, clients will receive a machine that will be efficient, productive, of high quality and that will satisfy all their requirements.